We all know that a table saw is a powerful tool. It can cut through even the thickest pieces of wood with ease. The thickness of the blade will determine the types of cuts you can make and how well your table saw functions. But how thick is a table saw blade?

In this blog post, we will be discussing the different thicknesses of table saw blades and what they are best used for. We will also run over some tips on how to choose the right blade for your project. After reading this post, you will know the different sizes of table saw blades and what each size is best used for so let’s start!

How Thick Is a Table Saw Blade?

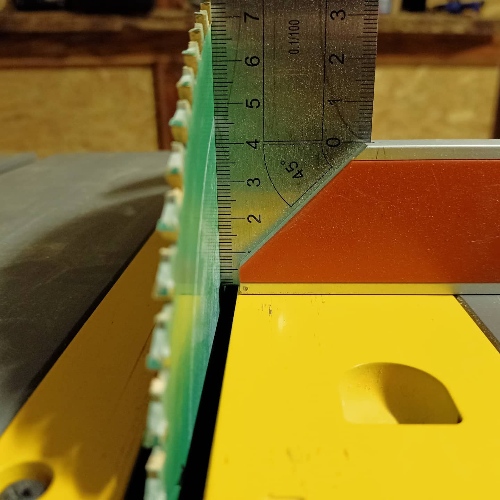

The average table saw blade is only about 1/8 of an inch thick. A table saw blade is typically around 1/16” to 1/8” thick, with 1/4” being the most common thickness for general use. The kerf, or width of the cut made by the blade, is also critical to consider typically, the wider the kerf, the more material is removed per cut. For example, a table saw blade with a 1/8” kerf will remove less material than one with a 1/4” kerf.

That’s not very thick at all! And yet, this thin blade can easily be cut through thick pieces of wood. So, how does it work?

How does it work?

A table saw blade is typically made from high-speed steel or tungsten carbide. It all has to do with the speed of the blade. A 12 inches table saw blade spins at a very high speed, typically around 3,450 to 4,000 revolutions per minute (rpm). (https://www.algebra.com/algebra/homework/conversion/Reduction-of-unit-multipliers.faq.question.395024.html)

This high speed allows the blade to easily cut through wood. And because the blade is so thin, it can make very precise cuts. That’s why table saws are so popular for making things like furniture and cabinets.

The type of material you are cutting will also play a role in how thick your table saw blade needs to be. Softer woods like pine or cedar can be cut with a thinner blade, while more difficult woods like oak or maple will require a thicker blade.

Types of Table Saw Blades and their Uses?

Table saw blades come in all shapes and sizes, each designed for a specific purpose. Here’s a quick rundown of the most common types of table saw blades so you can choose the right one for your next project.

Rip Blades

The purpose of rip blades is to cut along the grain of the wood. In contrast to crosscut blades, they usually have fewer teeth and are used for rip cuts (cuts that follow the grain of the wood).

Crosscut Blades

Crosscut blades are designed to cut across the grain of the wood. Generally used for crosscuts, they have more teeth than rip blades.

General Purpose Blades

General-purpose blades are designed to do a little bit of everything. They’re a good choice for most projects, but they’re not the appropriate choice for every project.

Combination Blades

Crosscuts and rip cuts are both possible with combination blades. Having both large and small teeth, they are a suitable choice for projects that require both types of cuts.

Specialty Blades

The purpose of specialty blades is to perform specific tasks, such as dado cuts, rabbet cuts, or molding cuts. They’re not a viable choice for almost anything.

Now that you know the different types of table saw blades, you can choose the right one for your next project. Just remember to always use the proper blade for the job at hand to ensure a safe and successful project.

How to choose a table saw blade According To Thickness Requirement?

When choosing a table saw blade, there are several factors to keep in mind:

- Type of table saw you have (portable, benchtop, or contractor)

- Size of the arbor hole on your saw’s motor

- The thickness of the material you’ll be cutting

- Type of cut you’ll be making most often

The 1/8 blades are the most popular because they can handle most cuts without issue. The 1/16-inch blades are designed for more demanding projects. 1/8″ blades are the thickest option and are typically used for cutting hardwoods. They’re also the most suitable choice for making crosscuts in materials that are 2″ or thicker.

1/16″ blades are the thinnest option and should only be used for rip cuts. They’re not suited for crosscuts because they can cause kickback if the material being cut is too thick. These blades can cut through thicker pieces of wood and are less likely to dull as quickly.

If you are just making simple cuts, a 1/8-inches blade will suffice. They’re especially well-suited for cutting thinner materials like plywood.

However, if you are working on a project that requires more precision, such as cutting curves, you will need a blade with a smaller diameter. You also need to consider the material you will be cutting and the type of project you will be working on.

Some blades are designed for specific materials, such as plywood or laminate. If you are unsure of what type of blade to choose, consult the manufacturer of your table saw.

Now that you know the different thicknesses of table saw blades, it’s time to choose the right one for your project. Keep these tips in mind and you’ll be sure to find the appropriate blade for the job.

FAQs

How thick is a Dewalt table saw blade?

A Dewalt table saw blade is typically between 10-inches thick. This is the most common thickness for a Dewalt table saw blade. However, it comes with 80 and 24-tooth options.

What is the tooth count of a Dewalt table saw blade?

The tooth count of a Dewalt table saw blade is 24,60 and 80.

What is the arbor size of a table saw blade?

The arbor hole generally follows the scale as it increases or decreases. An arbor hole diameter of 5/8″ is typical for blades with an 8″ or 10″ blade diameter.

What is the bore size of a table saw blade?

Circular blades have arbor holes of 1.5875 cm, but small woodcutting saw blades have arbor holes of 0.635 cm or 1.27 cm.

What is the maximum rpm of a table saw blade?

A typical table saw runs between 3,000 and 4,000 revolutions per minute. It is possible to decrease the blade rpm to 4,140 by enlarging the arbor pulley to 2 1/2 inches.

Final Thoughts

With so many different types of table saw blades on the market, it can be difficult to know which one to choose. However, by considering the type of table saw you have, the size of your arbor hole, the thickness of your material, and the type of cut you’ll be making most often, you can narrow down your options and find the right blade for your needs.

Choosing the right table saw blade thickness is paramount for getting the job done quickly and efficiently. Be sure to take into account the type of wood you’ll be cutting as well as the depth of the cut you need to make. With the right information, you’ll be sure to choose the appropriate table saw blade for the task at hand.

I am William Anderson and I’m the founder of this website. I started this site because I was tired of dealing with the problems that come with using Saw Tools. I wanted to help others avoid the time and frustration I had, So I started this site based on my own experience and what I’ve learned from other professionals and resources.